Components manufactured specifically for vehicles that have already been sold are aftermarket parts. At XRF Chassis, we carry aftermarket parts that are engineered not only to match but also to exceed the specifications of the parts produced by the original manufacturer. We achieve this by partnering with an original equipment manufacturing (OEM) testing laboratory and a state-of-the-art manufacturer. Our strategic partnerships enable us to enhance the quality and performance of auto parts.

OEM vs Aftermarket Parts

If you’re looking for value, increased durability, and long-term reliability, aftermarket components from XRF Chassis are an option you can trust. Here is a comparison of OEM and aftermarket car parts.

- Quality and durability: OEM parts are designed for standard use. XRF Chassis parts are made with heat-treated, high-grade steel that offers higher durability.

- Compatibility and fit: OEM parts fit perfectly as they are designed for specific vehicles. XRF Chassis uses CNC machining to design parts that match OEM dimensions, ensuring a precise fit.

- Engineering and performance: OEM parts are engineered to match original specifications. XRF Chassis components have thicker control arms, greaseable parts, and reinforced ball joints, making them ideal for heavy-duty use.

Features and Benefits

At XRF Chassis, we offer a range of features and benefits that make our aftermarket car parts ideal for customers looking for safe, durable, and reliable parts. Here’s a detailed look at some of these aspects:

- Reduced friction: Our reduced friction designs allow for easier movement of suspension and steering components. This enhances steering, handling, and fuel efficiency.

- Highly polished studs and step threads: Our high-quality step thread enables the installer to spin the nut by hand, providing the strongest thread possible.

- Acetal bearings: High-strength acetal bearings enhance load distribution, providing smoother steering, and better handling.

- Strong shells: When it comes to OEM vs aftermarket parts, the shells of replacement parts are often cold forged which causes the die to wear, preventing parts from having a consistent and precise fitment like OEM parts. At XRF Chassis, our aftermarket car parts are CNC machined to ensure a dimensional match to OEM parts.

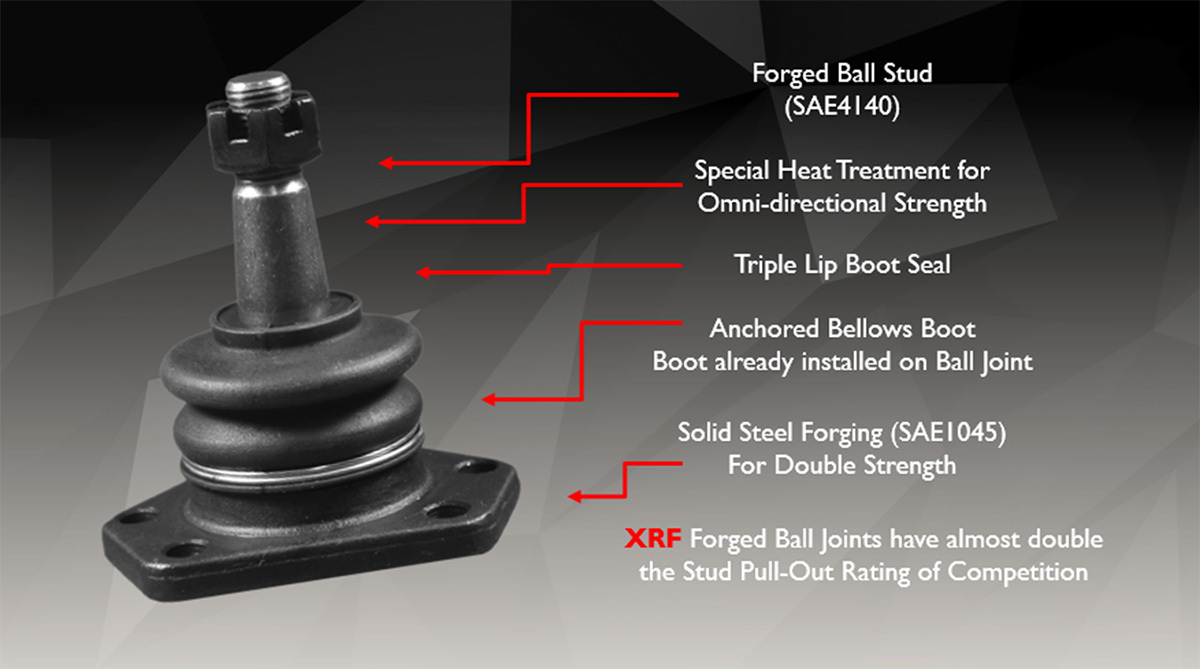

- Higher carbon tempered steel: XRF Chassis uses SAE1045 and SAE4140 mid-carbon steel, providing exceptional strength and durability.

- Sealed boots: Our boots are made from CR compound rubber which is resistant to oil, grease, brake fluid, battery acid, and ground-level ozone.

- Prepacked with grease: XRF Chassis components are prepacked with high-quality molybdenum disulfide grease.

- Forged steel housing: We’ve replaced conventional metal stamping ball joints with heavy-duty forged housings. This doubles the stud pull-out strength compared to competitors.

- Control arms: XRF Control Arms are the new industry standard for control arms. These parts are made with either forged steel, CNC-machined aluminum, or high-grade stamped steel.

XRF Chassis Parts

At XRF Chassis, our components are designed with precise specifications using CNC machining, enabling zero tolerance for variations and an ideal fit. Our aftermarket car parts also include all the hardware needed for a proper replacement of the original part. Contact us for more information about OEM vs aftermarket parts or place your order today and enjoy durable parts at cost-effective prices.