Today, we’re going to talk about a particular car material that plays a crucial role in XRF Chassis — SAE4140. This low alloy steel is known for its impressive strength, hardenability, toughness, and for being a unique steel with corrosion-resistance, making it an ideal choice for the structural components of a car. This high-quality steel is a key part of how XRF Chassis stands apart from the competition and makes us a go-to choice for supplying auto enthusiasts with reliable chassis parts.

Strength and Hardenability: The Science Behind the Steel

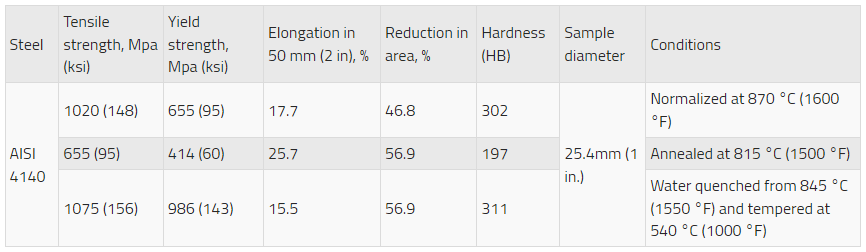

One of the key features of SAE4140 is its incredibly high strength. This steel has a tensile strength typically ranging between 655-740 MPa, which means this car material can withstand significant stress without deformation. This is particularly important in the context of a car, which needs to support the weight of both the vehicle itself and its passengers. Moreover, it needs to undergo the everyday physical stresses of driving on the road.

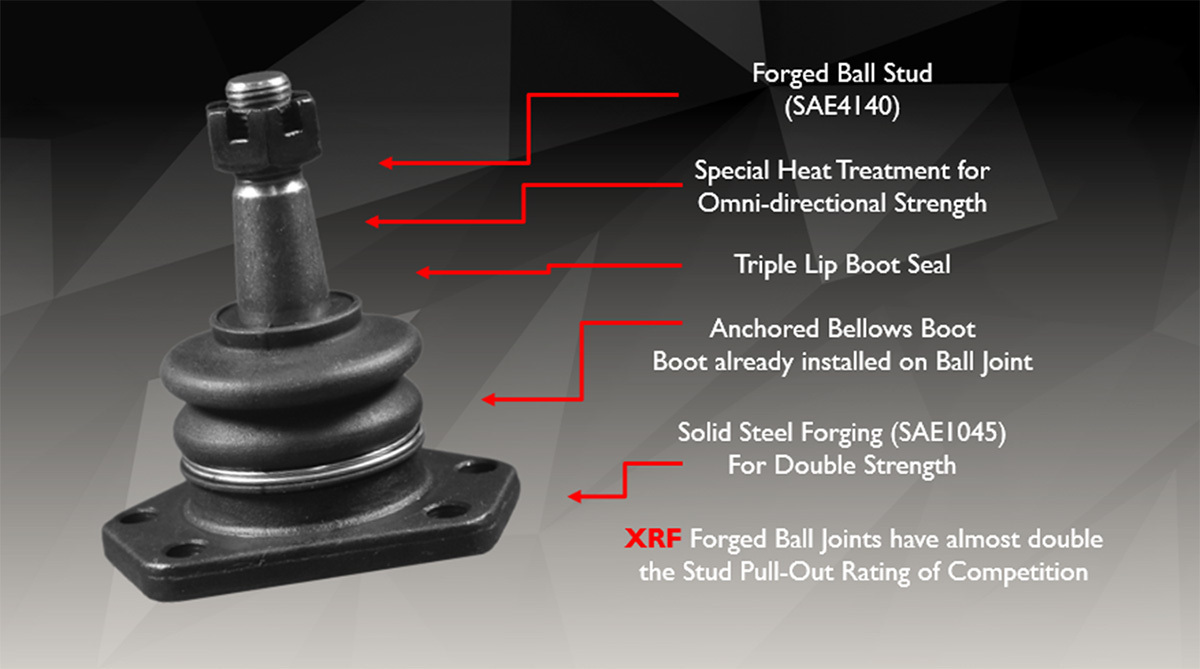

SAE4140 also has excellent hardenability. This means that it can be heat treated to a relatively high level of hardness, further enhancing its strength and wear resistance. This is crucial for parts that are subject to high wear and abrasion, such as the gears and shafts in a car’s transmission, or other components like ball joints, which are meant to provide support and smooth movement.

Let’s break down the science behind this steel’s incredible resilience: SAE4140’s chromium molybdenum composition creates a resilient microstructure that can withstand shear forces. When heat-treated with our proprietary techniques, this steel achieves a Rockwell hardness (HRC) of 28-32. This corrosion-resistant steel is perfect for parts such as ball joints in heavy-duty trucks like the F-250 or Ram 2500. And here’s the kicker — unlike cheap alloys that soften under heat, SAE4140 maintains its integrity even when temperatures spike to incredibly high levels.

(Table by www.theworldmaterial.com)

Toughness: Where Theory Meets the Road

Strength and hardenability aren’t the only important properties for car materials and components. They also need to be tough. In material science, toughness refers to the ability of a material to absorb energy and plastically deform without fracturing. In simpler terms, a tough material can take a hit and keep going without cracking or breaking.

When your vehicle suddenly drops into a pothole, the resulting shock sends powerful forces surging through the chassis. A car’s frame must absorb and distribute this force effectively. The remarkable toughness of SAE4140 allows it to handle these jarring impacts without developing cracks or suffering structural failure — providing crucial protection that shields both occupants and other car materials from the full brunt of collision forces in ways that less robust materials simply cannot match.

Mechanics have taken note of SAE4140’s resilience and how it can withstand virtually anything you throw at it. A Chevy Silverado could roll into the shop with a suspension arm that’s gone through three seasons of Michigan salt and curb collisions with a perfectly intact SAE4140 component given this steel’s corrosion resistance!

Precision Manufacturing: Why XRF Chassis’s Process Matters

SAE4140 is a stellar low-alloy steel for car parts, but it doesn’t become that way without work — it needs expert handling. Our partnership with an OEM-certified testing lab ensures our SAE4140 parts meet strict tolerance thresholds. Here’s how it’s done:

- Forging: Heated well above above 2,000°F and then shaped with a press

- Heat Treatment: It is quenched in a solution to achieve uniform hardness

- Machining: The parts are then CNC-tooled for extreme precision

The result? Parts that fit and function exactly as they should: tie rod ends that slot into Jeep Wranglers like they grew there. Control arm bushings that outlast factory parts on GMC Sierras. Our SAE4140 isn’t just steel — it’s steel with a pedigree.

SAE4140 vs. The Competition

Why choose SAE4140? Why not use 4340, which is stronger, or 4130, which is more affordable?

While 4340 offers higher strength, the added benefit of this car material is unnecessary for most conventional automotive applications and the price tag makes it out of reach for most consumers. SAE4130 is great for things such as roll cages, but it lacks the resistance needed for daily-driven vehicles. SAE4140 high corrosion-resistance steel sits in that Goldilocks spot of meeting all your durability needs whilst being completely affordable!

From Foundry to Freeway: Real-World Applications

You will find SAE4140 in several key XRF components, such as our:

- Ball Joints: Forged eyes withstand 360° of articulation in off-road conditions

- Sway Bar Links: Resists fatigue from constant torsion forces

- Pitman Arms: Handles steering loads from lifted trucks without deformation

With cheaper aftermarket car materials you might notice that they start to develop play after a small amount of miles — that’s the result of inferior metallurgy that isn’t up to the task. By contrast, our SAE4140 components have contributed to shops reporting much fewer returns and warranty claims on suspension work.

Built to Last: The Sustainability Angle

Durability is sustainable in two respects: it’s eco-friendly and good for your pocketbook. SAE4140’s corrosion resistance translates to fewer replacements over a vehicle’s lifespan. Fewer replacements means less waste and fewer trips to the shop for replacement car materials.

On top of that, whether you’re using the part for your vehicle or installing it in your shop, you save money both on parts and in avoiding warranty payments for customers! Pair this steel with corrosion resistance with our 3 year or 36,000 mile warranty, and you’ve got a recipe for components that outlive payment plans!

Conclusion

The versatility of SAE4140 explains its widespread adoption throughout automotive manufacturing. Engineers value this alloy for its remarkable combination of strength, superior hardenability, and impressive toughness — qualities that make it particularly well suited for critical structural components that must bear substantial loads while maintaining reliability under stress. Consider this car material’s contribution next time you’re behind the wheel — these specialized steel components silently ensure your journey remains secure. We’ll explore other fascinating industrial materials in future discussions that continue to shape the world of vehicles and car repair around us.

Ready to experience the difference that SAE4140 makes? Explore our SAE4140 parts or join our membership program for 10% off your orders! Have questions? Don’t hesitate to contact us!

Reference

SAE AISI 4140 Steel Properties, Material Heat Treatment, Rockwell Hardness (theworldmaterial.com)